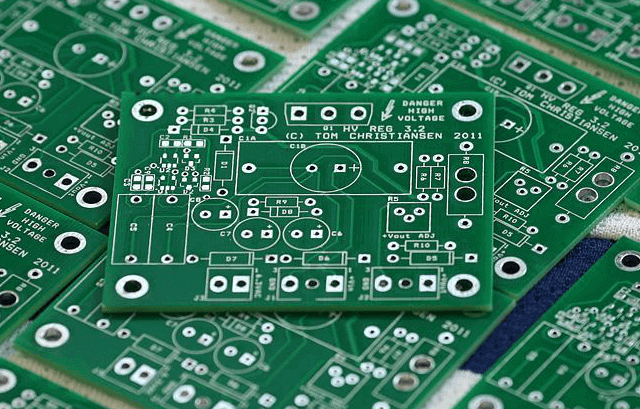

PCB manufacturing is the process of creating a circuit board for an electronic device such as a computer. The first step in this process is to create a custom batch of PCB-grade epoxy. This epoxy can be mixed with other ingredients, depending on what type of board will be made. The next step in the PCB manufacturing process is to etch the two copper layers used for connecting circuits on either side of the insulating material. After that, various electronic components can be soldered to them and then they are tested.

What Are PCB Boards Used For?

PCBs are used to make the smallest electronic circuits. They are tough, durable and are laid out on layers that have a copper coating over a plastic material. PCBs can be used in both domestic and industrial applications. Examples of consumer products that use PCBs include stereos, computers, TV’s, cell phones and even refrigerators.

How Are PCB Boards Made?

After the circuit is designed, the next step in the manufacturing process is to prepare for PCB manufacturing. First, a custom batch of PCB-grade epoxy is formed. The epoxy can be mixed with other ingredients, depending on what type of board will be made. The epoxy mixture will then be heated until it becomes a liquid state. It then begins to solidify and harden into a semi-transparent film. The next step is to etch the two copper layers that make up the electronic circuit. After etching, various electronic components can be soldered to them and then they are tested for errors.

How Are PCB Boards Validated?

PCB manufacturing uses a thorough testing process to make sure that each board works properly before it is shipped. A small percentage of them are randomly chosen and put through more extensive testing in different areas of the circuitry. The tests are repeated until only a very small number of boards have malfunctions. Only then are they sent to the manufacturer of the product they are being made for.

Why Are PCB Boards Used?

PCB manufacturing became a reliable way to mass produce electronic circuits because it is cheaper and more efficient than other methods. The board design can be changed quickly and easily by simply altering the design on the computer. This is much faster than having to create separate, custom boards with each of the small changes in the circuitry. PCBs also use less material than other methods, which saves money.

How Long Does It Take to Manufacture a PCB?

The time it takes for PCB manufacturing depends on the complexity of the product being manufactured. The average time is about six weeks. This includes everything from designing the product to manufacturing the board and testing it. The time frame can be shortened somewhat if there is an existing design that can be modified for the new project.

PCBs are used in a variety of electronic devices. Much like how computer chips have become smaller and smaller, the PCBs themselves have also shrunk. This is because it becomes cheaper to produce them for every decreasing size. PCBs are not only created for consumer goods, but they are also now being utilized in many industrial applications as well.